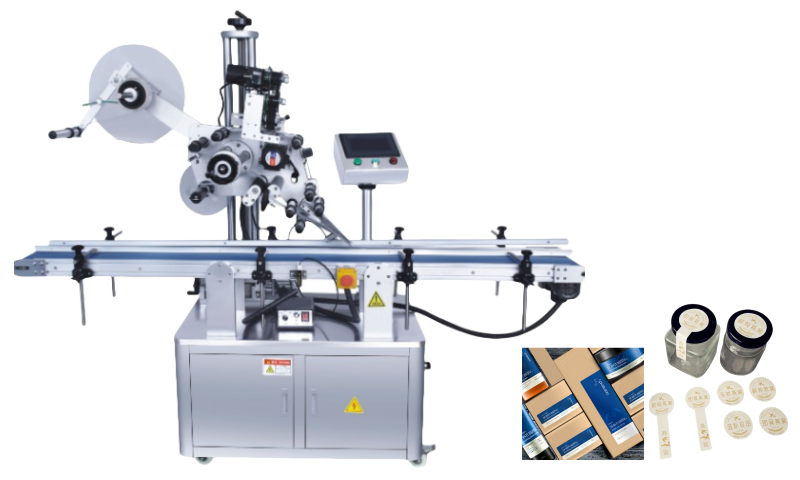

Main characteristic

Automatic horizontal round bottle labeling machine, can be applied to a test tube, oral liquid, batteries and other products with standard.Special shapes can be customized consulting manufacturer

Features

● Adopt roller conveyor of horizontal type.Conveying chain tilting be able to achieve stable horizontal labeling.Labeling speed up to 200 bottles/min.Save a lot of

manpower and resources.

● Adopt flexible bottle separating device and label covering device. Bottle breakage rate under 1 in 100,000.

●Labeling and covering happens simultaneously,high overlapping coefficient of labeling,the label is neat with no bubble ,no wrinkle,improve packing quality .

● The use of the advanced electronic control system with Panasonic PLC + Panasonic touch screen + Panasonic needle electronic eye + German Leuze electronic eye for detecting label supports the equipment to run 7x24 hours.

Intelligent control

● Automatic photoelectric tracking, no labeling without object, automatic correction without label and automatic detection function, can prevent missing label and wasting label.

● All the equipments are mainly made of stainless steel and high grade aluminum alloy.and the whole structure is strong enough, which meets the GMP requirements.

● Has the function of fault alarm, counting function of the production, saving electricity function, setting production quantity and prompting function, setting parameters and protecting function.

● Optional function

Hot play yards / spurting code function

b)Automatic applicator

c)Automatic collecting function (according to product)

Working principle

Bottle dividing device separate product,put the product to the conveyor belt ,sensor detects the passed product, returned signals to the labeling control system, send out the label by motor of the control system at the right moment, and stick to labeling position of the product, cover label at the same time, sticking two label movement is concluded.

Technical parameters

(This is the configuration of standard machine,the machine can be customized according to customer’s special requirement.

|

Applicable Length of Label |

20mm~100mm |

|

Applicable Width of Label |

20mm~130mm |

|

Applicable diameter of product |

φ10mm~30mm |

|

Applicable outside diameter of label roll |

φ280mm |

|

Applicable Inside diameter of label roll |

φ76mm |

|

Accuracy of labeling |

±0.5mm |

|

Feeding label speed(m/min) |

Stepper motor:5~19m/min |

|

Labeling speed(pcs/min) |

Steppe motor:100~200pcs/min |

|

Conveying speed(pcs/min) |

450pcs/min |

|

Weight (kg) |

about 200kg |

|

Frequency(HZ) |

50HZ |

|

Voltage(V) |

220V |

|

Power(W) |

Stepper motor:1020W |

|

Equipment external dimensions(mm)(L*W*H) |

2050mm*650mm*1450mm |

© 1999-2024 Hitech123.com. All rights reserved.